Structural NDT Testing

Implement advanced Structural NDT Testing with Wire Consultancy. Our non-destructive testing and positive material identification techniques offer businesses a comprehensive assessment of asset integrity, reliability, and quality. With a focus on precision and efficiency, we provide accurate results and valuable insights to optimize maintenance strategies and ensure compliance with regulations.

We Strive to Drive

Safety Culture

What is Structural NDT Testing?

Structural NDT Testing is a critical aspect of assessing the health and strength of structures without causing any damage. In the context of RCC and Steel Structures, Structural NDT Testing plays a pivotal role in identifying potential issues such as cracks, corrosion, and material defects, allowing for timely and proactive maintenance.

Benefits of Structural NDT Testing

- Early detection of potential structural issues.

- Compliance with regulatory requirements.

- Increased safety and longevity of structures.

- Cost-effective compared to traditional destructive testing.

- Optimized maintenance strategies.

- Improved structural performance.

- Minimizes downtime and disruptions to operations.

- Environmental sustainability.

Types of Structural NDT Testing for RCC and Steel Structures

- Visual Testing (VT): Direct visual inspection to identify surface imperfections like cracks, surface corrosion, deflection, loosening, spalling & more.

- Drone Survey: Aerial inspection using drones to capture high-resolution videos, providing a bird’s-eye view for a comprehensive assessment of structures and facilities.

- Thermography: Infrared imaging technology reveals temperature variations to detect hidden issues like insulation gaps, delamination and water leaks in structures.

- Rebar Locator: Utilizing magnetic waves to locate and assess reinforcement bars in concrete, ensuring structural integrity by checking the concrete cover and diameter of bars.

- Ultrasonic Pulse Velocity Testing (UPV): Evaluates the integrity of concrete structures by measuring the speed of pulses, providing insights into material homogeneity and potential defects.

- Schmidt Hammer (Rebound Hammer): Assessing concrete strength instantly by measuring the rebound of a spring-loaded hammer.

- Half-Cell Potential: Evaluating the corrosion potential of reinforcing steel in concrete to identify areas prone to corrosion and guide preventive measures.

- Carbonation (Concrete Alkalinity): Measuring the alkalinity levels within concrete to assess the risk of carbonation and potential corrosion of embedded steel.

- Magnetic Particle Testing (MPT): Detecting surface and near-surface flaws in ferrous materials by applying magnetic fields and observing particle accumulations at defect locations.

- Dye Penetration Testing (DPT): Identifying surface-breaking defects in materials by applying a coloured dye, enhancing visibility of flaws for precise detection.

- Eddy Current Testing: Detecting surface and near-surface defects in conductive materials, offering a non-invasive and efficient method for quality assessments in various industries using electromagnetic fields.

- Phased Array Ultrasonic Testing (PAUT): Employing advanced ultrasonic techniques with multiple transducer elements for detailed imaging and flaw characterization in various materials.

- Short Range Ultrasonics (SRUT): Provides detailed assessments of material thickness, corrosion, and other defects in a non-contact manner, ensuring precise structural evaluation using ultrasonic waves.

Standards Adopted for Structural NDT Testing

Wire Consultancy strictly adheres to international standards for NDT, ensuring the highest level of accuracy and reliability in our assessments. Our team follows guidelines from organizations such as ASTM, ASNT, and ISO, guaranteeing that your structures meet or exceed industry requirements.

- BRITISH STANDARD (BS) 3923 Part 1

- AMERICAN SOCIETY FOR TESTING AND MATERIALS (ASTM) C597

- AMERICAN SOCIETY FOR TESTING AND MATERIALS (ASTM) C805

- AMERICAN SOCIETY FOR TESTING AND MATERIALS (ASTM) C 876 – 91

- AMERICAN CONCRETE INSTITUTE (ACI) 201.1R-08

- BRITISH STANDARD (BS) 6072:1981

- BRITISH STANDARD (BS) 3889 (part 2A)

- INTERNATIONAL ORGANIZATION FOR STANDARDIZATION (ISO) 3452

- AMERICAN SOCIETY FOR TESTING AND MATERIALS (ASTM) E2700-09

Methodology of Structural NDT Testing Services

The meticulous application of Structural NDT methodologies offered by Wire Consultancy serves as a proactive measure to identify potential issues, mitigate risks, and enhance the overall safety and reliability of structures and components. Our commitment to excellence ensures that your assets meet the highest standards, contributing to the success and longevity of your projects.

Applications of Structural NDT Testing Across Diverse Industries

1. Construction

Quality Assurance: In the construction industry, Structural NDT Testing ensures the quality and integrity of newly erected buildings and infrastructure. By identifying any hidden defects or structural issues early on, builders can rectify problems before they become major concerns.

2. Oil and Gas

Pipeline Integrity: Structural NDT Testing plays a critical role in ensuring the integrity of pipelines used in the oil and gas sector. By detecting corrosion, cracks, or other potential issues, our testing services help prevent leaks and enhance the overall safety of the pipeline network.

Storage Tanks: Regular inspections using Structural NDT methods are vital for assessing the condition of storage tanks. This ensures that these structures can safely contain hazardous materials without risk of leaks or structural failure.

3. Infrastructure

Bridges and Viaducts: Structural NDT Testing is essential for assessing the structural health of bridges and viaducts. By identifying any deterioration, corrosion, or fatigue in the materials, our testing services contribute to the maintenance and longevity of these critical transportation structures.

Dams and Tunnels: Structural NDT Testing is employed to evaluate the integrity of dams and tunnels. Identifying potential issues such as cracks or voids helps prevent catastrophic failures, safeguarding both infrastructure and surrounding communities.

4. Manufacturing

Fabricated Steel Components: Industries involved in manufacturing steel components, such as beams, columns, and other structural elements, benefit from Structural NDT Testing to ensure the quality and reliability of the fabricated materials. This is crucial for maintaining the structural integrity of the final products.

Weld Inspections: Structural NDT Testing is commonly used for inspecting welds in manufacturing processes. This helps detect any welding defects or discontinuities that could compromise the strength and durability of welded joints.

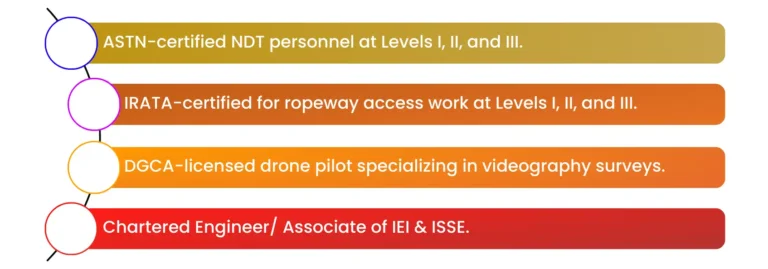

Team Capability for Structural NDT Testing

Our NDT team consists of highly qualified and experienced professionals with a proven track record in assessing RCC and Steel Structures. They are equipped with the latest technologies and methodologies to deliver precise and timely results. Continuous training and skill development ensure that our team stays at the forefront of NDT advancements.

Choose Wire Consultancy for Structural NDT Testing Services

Choose Wire Consultancy for unparalleled expertise in RCC and Steel Structures NDT Testing. Our commitment to quality, safety, and innovation sets us apart in the industry. Contact us today to discuss your project requirements and ensure the longevity of your structures.

Our team of experienced consultants is ready to collaborate with you to achieve your engineering, safety and sustainability goals. Get in touch with us to learn more.

Global Presence

UAE – Dubai, Abu Dhabi

Saudi Arabia – Dammam, Rayadh, Jeddah

Oman – Muscat, Salalah

Qatar – Doha

India – Delhi, Hyderabad

For Business Enquiry

Info@wireconsultants.com

For HR Enquiry

hr@wireconsultants.com

Copyright © 2024 Wire Consultancy | All Rights Reserved