Magnetic Particle Testing (MPT) Services

At Wire Consultancy, we’re driven by the ethos of proactive asset management. Our expertise lies in Magnetic Particle Testing (MPT), an advanced Non-Destructive Testing (NDT) technique crafted to unveil internal flaws, securing the structural robustness of your crucial assets. Committed to precision, we deliver meticulous defect identification and reliable assessments, empowering you to make judicious decisions regarding the maintenance and performance of your invaluable assets.

We Strive to Drive

Safety Culture

Certified Consultants

What is Magnetic Particle Testing?

Magnetic Particle Testing (MPT) stands out as a widely embraced and cost-effective non-destructive examination (NDE) technique for ferromagnetic materials. Ferromagnetic materials are those that can be magnetized or strongly attracted by a magnetic field. MPT is adept at scrutinizing surface discontinuities and, to some extent, can unveil subsurface irregularities. The method is particularly effective in detecting flaws situated just below the surface, although its sensitivity diminishes as depth increases.

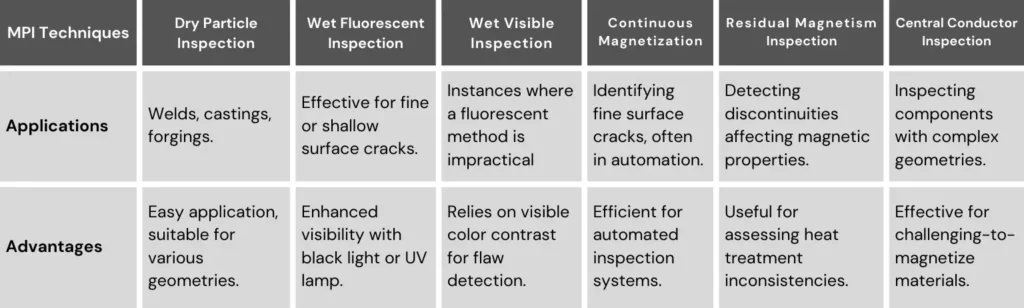

Magnetic Particle Testing (MPT) Techniques

Magnetic Particle Testing (MPT) encompasses various techniques, each tailored to specific applications and material conditions. Understanding these diverse methods enhances the flexibility and effectiveness of flaw detection in ferromagnetic materials. This table provides a concise comparison of various Magnetic Particle Testing (MPT) techniques, highlighting their distinct characteristics, applications, and advantages.

Benefits of Magnetic Particle Testing

Magnetic Particle Testing (MPT) have several advantages over alternative non destructive testing (NDT) techniques such as visual inspection and dye penetration testing. Unlike visual inspection, MPT has the capability to reveal not only surface irregularities but also subsurface and internal defects, providing a more comprehensive assessment of material integrity. This makes MPT particularly valuable in applications where hidden flaws may compromise structural reliability. Moreover, MPT is specifically designed for ferromagnetic materials, expanding its versatility to a wide range of components. The automation potential of MPT streamlines the inspection process, enhancing efficiency and precision compared to the manual application often associated with dye penetration testing.

Furthermore, MPT offers the benefit of providing both qualitative and quantitative data, supplying a more detailed and comprehensive evaluation of the inspected material. In terms of safety and environmental impact, MPT is advantageous as it is non-hazardous, ensuring the well-being of inspectors and minimizing potential harm to the surrounding environment—further solidifying its position as a superior NDT method.

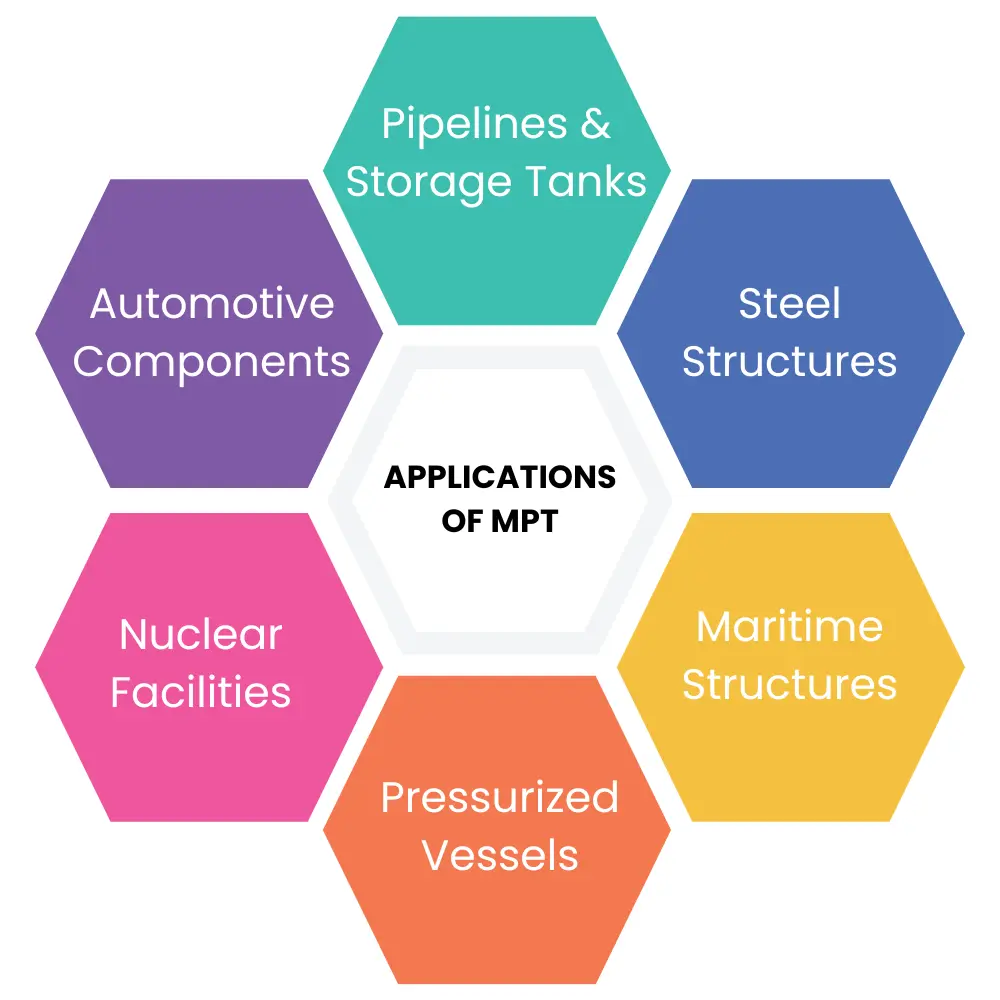

Applications of Magnetic Particle Testing

- Weld inspection: Assess weld quality and identify potential defects.

- Castings and forgings inspection: Detect cracks, porosity, and shrinkage cavities.

- Storage tank inspection: Identify surface cracks and corrosion in tank walls.

- Machinery and equipment inspection: Ensure surface integrity of critical components.

- Aircraft and aerospace components: Inspect landing gear and engine parts for surface flaws.

Magnetic Particle Testing Standard Code

Our Magnetic Particle Testing (MPT) services are conducted in strict adherence to industry-leading standards, reflecting our dedication to delivering top-tier quality and reliability. Committed to upholding the highest benchmarks, we align our practices with globally recognized standards such as ISO 9934 which provide comprehensive guidelines for magnetic particle inspection techniques. Additionally, our procedures comply with the rigorous requirements set forth by ASME Section V Article 7, ensuring our adherence to stringent regulations within the boiler and pressure vessel industry. Our commitment extends beyond international standards, encompassing local benchmarks like IS 3664.

By integrating these esteemed standards into our MPT processes, we assure our clients of the accuracy, consistency, and compliance of our services, establishing a foundation of excellence in line with industry best practices. In the case of specific needs, such as inspecting aerospace applications, the ASTM E1444/E1444M-22a standard is employed to conduct magnetic particle testing on ferromagnetic materials utilizing the wet fluorescent method. Standards Includes:

- ASTM E1444: Outlines the standard practice for MPT, covering equipment, procedures, and personnel qualifications.

- ISO 9934: Provides international guidelines for MPT, ensuring consistent quality and global acceptance of inspection results.

- ASME Section V Article 7: Specifies requirements for MPT in boiler and pressure vessel applications, upholding safety standards in these critical industries.

- EN 1290: European standard for MPT, ensuring compliance with European regulations and quality expectations.

Choose Wire Consultancy for Magnetic Particle Testing (MPT) Services

Experience unmatched precision and reliability with Wire Consultancy’s team of ASNT Level 1 and Level 2 certified professionals specializing in Magnetic Particle Testing (MPT). Our experts have undergone rigorous training and examinations, meeting the stringent standards set by the American Society for Non-destructive Testing (ASNT). ASNT Level 1 certification ensures proficiency in basic MPT examinations, while our Level 2 certified technicians showcase advanced expertise, from conducting inspections to interpreting results and making critical decisions.

At Wire Consultancy, we excel in diverse MPT techniques, tailoring inspections to your unique requirements. Navigating complex geometries, interpreting intricate data, and delivering detailed reports with actionable insights, our MPT services guarantee a thorough assessment of your critical assets.

Our Methodology

- Surface preparation: Cleaning and demagnetizing the inspection area for optimal particle attraction.

- Magnetization: Applying a strong magnetic field to the material using electromagnets or permanent magnets.

- Particle application: Dry or wet particles are applied to the magnetized surface.

- Defect identification: Particles accumulate around surface discontinuities, visible to the naked eye or under UV light.

- Evaluation and reporting: Experienced technicians analyze the particle patterns and document findings in a detailed report.

Magnetic Particle Testing Services Deliverables

- Comprehensive inspection reports: Including images, diagrams, and data analysis for informed decision-making.

- 3D visualizations: (for specific MPT techniques) Providing enhanced clarity of surface defects.

- Recommendations for further action: Tailored advice on repairs, maintenance, or life extension strategies.

Contact

Feel free to contact us for any questions and query

Connecting with Us is Just a Click Away – Let’s Begin Your Project Hassle Free.

Our team of experienced consultants is ready to collaborate with you to achieve your engineering, safety and sustainability goals. Get in touch with us to learn more.

Our Presence

Noida

Office-03, First Floor, D-53, Sector-2,

Noida, Uttar Pradesh-201301, India

Hyderabad

SF-LM-13, Lumbini Jewel Mall

Banjara Hills Road no 2

Hyderabad 500034

For Business Enquiry

For HR Enquiry

hr@wireconsultants.com

+91-7827931701

Copyright © 2024 Wire Consultancy | All Rights Reserved