Ultrasonic Testing (UT) Services

At Wire Consultancy proactive asset management is our guiding principle. We specialize in Ultrasonic Testing (UT), an advanced Non-Destructive Testing (NDT) technique designed to identify internal flaws and guarantee the structural integrity of your crucial assets. Our commitment lies in delivering precise defect detection and reliable assessments, empowering you to make well-informed decisions regarding the maintenance and performance of your critical assets.

We Strive to Drive

Safety Culture

Certified Consultants

What is Ultrasonic Testing (UT)?

Ultrasonic Testing relies on high-frequency sound waves to uncover internal flaws in materials. By emitting ultrasonic waves into a material, the technology detects reflections caused by defects, allowing for precise flaw location and characterization. These waves reflect off internal discontinuities like cracks, voids, and corrosion, producing data analysed to pinpoint their location and size. Imagine shining a sound flashlight through an object, revealing hidden flaws invisible to the naked eye. This versatile technique provides precise insights into material integrity, ensuring the safety and reliability of critical assets across diverse industries.

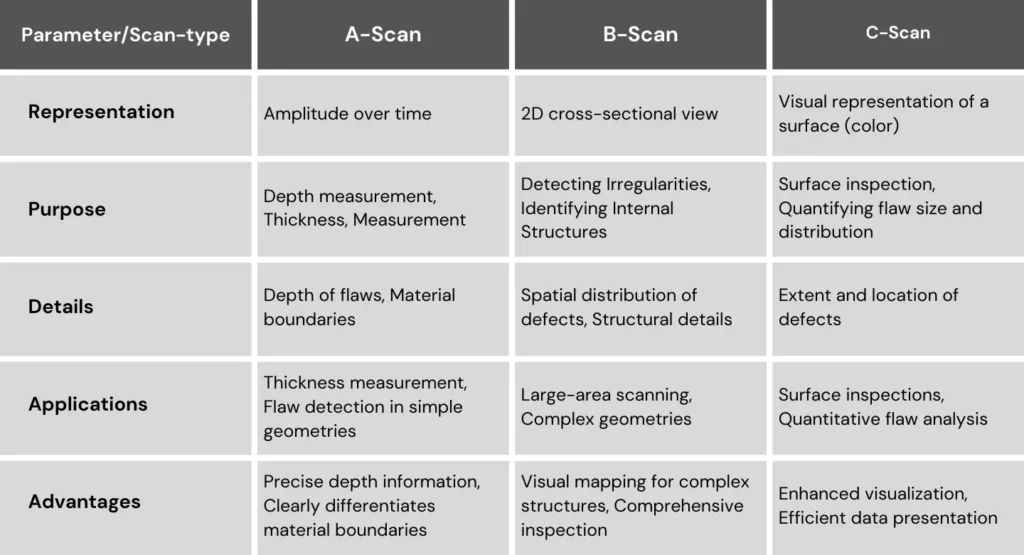

Ultrasonic Scan Techniques

Ultrasonic testing has different techniques like A-scan, B-scan & C-scan to examine different specimens. Each of these Ultrasonic scans serves distinct purposes, collectively contributing to a comprehensive inspection process and empowering professionals with valuable data for informed decision-making in various industries.

Ultrasonic Testing Methods

Two primary methods employed within Ultrasonic Testing are Straight Beam Testing and Angle Beam Testing, each designed to address specific inspection needs with precision and efficiency.

1. Straight Beam Testing

Straight Beam Testing is a fundamental Ultrasonic Testing method employed to assess materials for internal defects. In this technique, ultrasonic waves are directed straight into the material at a perpendicular angle, allowing for the detection of flaws such as cracks, voids, or laminations. The reflected waves are then analysed to determine the depth, size, and nature of any detected anomalies.

Straight Beam Testing is particularly effective for inspecting welds, forgings, and other components where a direct and perpendicular approach is feasible. This method is vital for assessing the structural integrity of critical assets, ensuring that flaws are identified with precision.

2. Angle Beam Testing

Angle Beam Testing is a specialized Ultrasonic Testing technique designed for the examination of materials at oblique angles. By introducing ultrasonic waves into the material at an angle, typically 45 or 60 degrees, this method is adept at detecting flaws that might be missed by straight beam testing.

Angle Beam Testing is commonly used to inspect welds for defects such as lack of fusion or cracks perpendicular to the beam direction. It offers versatility in assessing complex geometries and is particularly valuable for applications where access is restricted.

Benefits of Ultrasonic Testing

- Non-Destructive Assurance: Safeguards assets without causing damage.

- Unmatched Precision: Identifies even tiny defects with accuracy.

- Versatile Application: Works across metals, plastics, and composites.

- Cost-Effective Prevention: Averts breakdowns, extends asset lifespan.

- Time-Efficient Inspections: Swift and thorough assessments.

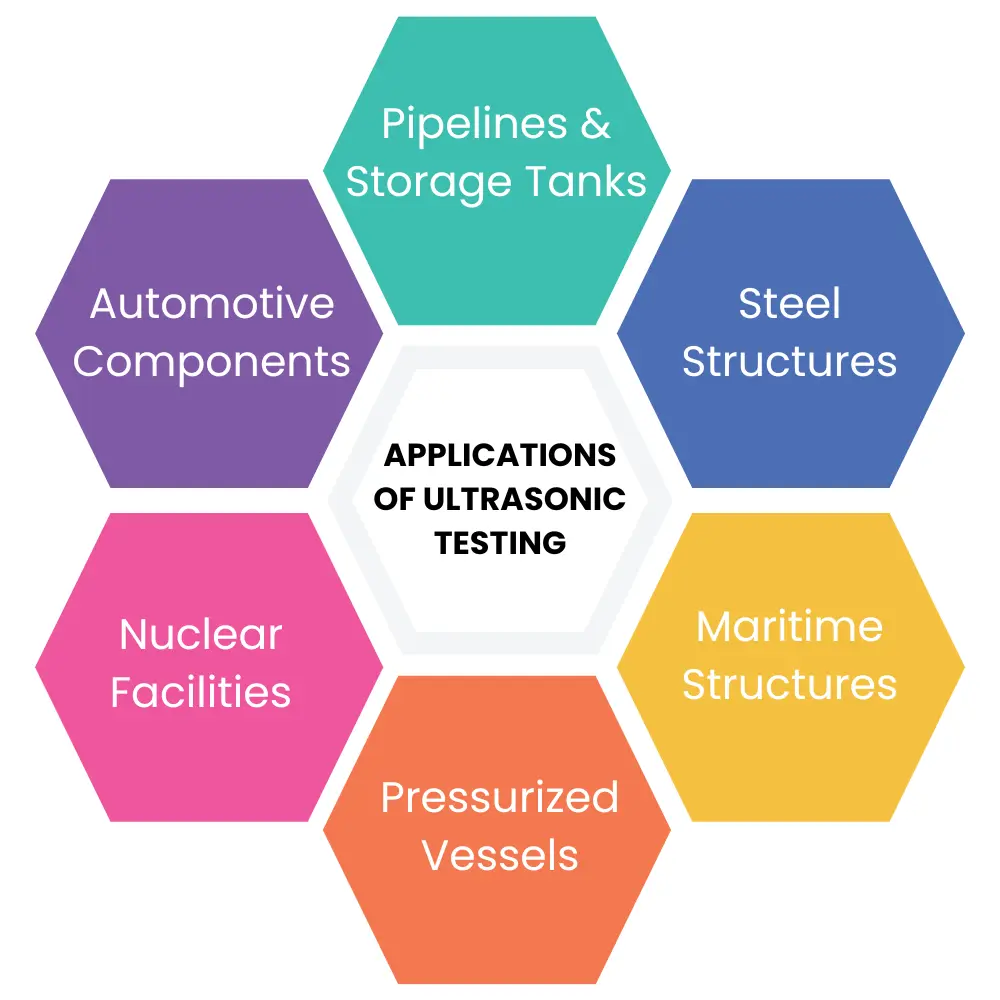

Applications of Ultrasonic Testing

- Pipeline integrity: Detect cracks, corrosion, and wall thinning in pipelines.

- Pressure vessel inspection: Ensure the safety and reliability of pressure vessels.

- Weld inspection: Assess weld quality and identify potential defects.

- Material characterization: Measure thickness, grain size, and other material properties.

- Aircraft and aerospace components: Inspect critical components for fatigue cracks and other flaws.

Ultrasonic Testing Standard Codes

Our Ultrasonic flaw detection services adhere to a rigorous set of industry standards to ensure the highest quality and reliability. We follow internationally recognized standards such as ISO 17640, ASTM E114, which provides guidelines for the ultrasonic examination of welds. Additionally, our practices align with the ASME Section V Boiler and Pressure Vessel Code, ensuring compliance with stringent regulations in the field. Our commitment to excellence extends to local standards as well, with adherence to IS 3664. By incorporating these standards and more into our Ultrasonic flaw detection processes, we guarantee the accuracy, consistency, and compliance of our services with industry best practices. Standard includes:

- ASTM E797: Defines the standard practice for measuring material thickness using UT.

- ASTM E114: Outlines the standard practice for straight-beam contact UT testing, commonly used for general defect detection.

- ASTM E164: Provides standards for contact UT of welds, ensuring proper assessment of weld integrity.

- ASTM E317: Establishes the standard practice for evaluating the performance characteristics of UT instruments and systems, guaranteeing the accuracy and reliability of the data acquired.

- ASME Section V Article 4: Specifies the requirements for ultrasonic examination in boiler and pressure vessel applications, ensuring compliance with safety regulations.

- ISO 17640: Provides international guidelines for UT of welds, outlining various techniques, testing levels, and assessment criteria.

Choose Wire Consultancy for Ultrasonic Testing

At Wire Consultancy, our commitment to precision and reliability is reflected in our team of ASNT Level 1 and Level 2 certified personnel who specialize in Ultrasonic Testing (UT). These highly skilled professionals have undergone rigorous training and examination processes set by the American Society for Non-destructive Testing (ASNT). ASNT Level 1 certification denotes proficiency in conducting basic UT examinations under the supervision of higher-level personnel, ensuring adherence to industry standards. Our ASNT Level 2 certified technicians, on the other hand, demonstrate advanced expertise in not only performing UT but also interpreting results, setting up and calibrating equipment, and making critical decisions regarding the inspection process.

We master diverse techniques like pulse-echo and thickness gauging, tailoring inspections to your specific needs. Our expertise lies in navigating complex geometries, interpreting intricate data, and delivering comprehensive reports with actionable insights.

Our Ultrasonic Testing Methodology

- Planning and preparation: Identifying inspection points, selecting appropriate UT techniques, and ensuring safety protocols.

- Data acquisition: Skilled technicians utilize UT probes to send and receive sound waves, capturing data on internal anomalies.

- Data analysis: Experienced engineers interpret the acquired data, identifying and sizing defects.

- Reporting and recommendations: Comprehensive reports detail findings, potential risks, and recommendations for further action or repair.

Ultrasonic Testing Services Deliverables

- Detailed Reports: Comprehensive documentation of Ultrasonic Testing findings, including flaw sizes, locations, and overall structural analysis.

- 2D/3D Visualization: Clear and visually intuitive representations of internal geometry, aiding in a better understanding of structural integrity.

- Recommendations for Improvement: Actionable insights and suggestions to enhance infrastructure service life, based on the identified flaws and structural assessments.

Contact

Feel free to contact us for any questions and query

Connecting with Us is Just a Click Away – Let’s Begin Your Project Hassle Free.

Our team of experienced consultants is ready to collaborate with you to achieve your engineering, safety and sustainability goals. Get in touch with us to learn more.

Our Presence

Noida

Office-03, First Floor, D-53, Sector-2,

Noida, Uttar Pradesh-201301, India

Hyderabad

SF-LM-13, Lumbini Jewel Mall

Banjara Hills Road no 2

Hyderabad 500034

For Business Enquiry

For HR Enquiry

hr@wireconsultants.com

+91-7827931701

Copyright © 2024 Wire Consultancy | All Rights Reserved