Energy efficiency has become a core business priority for organizations across India. Industrial facilities, commercial buildings, data centers, retail distribution hubs, and large offices all face rising operational costs, stricter compliance expectations, and increasing stakeholder pressure to demonstrate sustainability. In this environment, an energy audit is no longer just a technical evaluation; it is a strategic tool for long-term performance, resilience, and profitability.

An energy audit studies how energy enters and flows through a facility and identifies where and why losses occur. When conducted by qualified experts, it delivers concrete strategies to reduce energy consumption, lower operating costs, and improve equipment reliability. This guide explains the full scope of energy auditing in a concise and practical format, incorporating real-world Indian examples and highlighting why professional support from organizations like Wire Consultancy drives stronger outcomes.

The Science Behind Energy Audits: Understanding Waste and Efficiency

Energy audits are grounded in engineering principles, especially the first law of thermodynamics: energy can only change form. Waste occurs when a significant fraction of energy is converted into heat, friction, noise, or unwanted movement.

In a textile mill in Tiruppur, for example, motors generate excessive heat due to misalignment and poor bearing lubrication. This heat represents energy loss. Similarly, a retail fulfillment center in Bengaluru may run HVAC systems at unnecessarily low temperatures, causing avoidable energy spikes.

The strategic purpose of an energy audit is to improve output without increasing energy input, thereby decoupling productivity from consumption. Organizations gain immediate OPEX savings and long-term CAPEX benefits through reduced downtime and extended equipment life.

The Four Pillars of an Effective Energy Audit

1. People: Human Behavior and Operational Culture

Energy efficiency often deteriorates due to behavior. In cold storages around Navi Mumbai, workers sometimes leave dock doors open during loading, causing refrigeration compressors to run continuously.

2. Process: How Workflows Are Designed

Inefficiencies occur when equipment sequences or operating schedules do not match real demand. A bottling plant in Gujarat ran conveyors during idle periods, wasting thousands of kilowatt-hours every month.

3. Place: Building Structure and Environment

Poor insulation, excessive glazing, or roof heat gain significantly impacts energy use. In Chennai’s export zones, weak roof insulation often leads to 20 to 30 percent more HVAC consumption during peak summer.

4. Performance: Equipment Condition and Efficiency

Motors, chillers, compressors, boilers, and pumps naturally degrade. In a Faridabad automotive unit, old compressors operated at 30 percent below design efficiency due to internal leakage and wear.

Together, these elements define the energy consumption ecosystem.

Types of Energy Audits and Their Purpose

Level 1: Walk-Through Audit

A quick screening assessment designed to identify visible inefficiencies.

Example: A Pune shopping complex discovered that 40% of corridor lights were kept ON during broad daylight.

Level 2: Detailed Energy Audit

The most widely used method, involving instrumentation, measurements, and load studies.

Example: A Morbi ceramic unit cut its compressed air energy cost by INR 18 lakh annually by fixing leaks and optimizing pressure.

Level 3: Investment-Grade Audit (IGA)

Used for CAPEX-heavy decisions and performance contracts with financiers.

Example: A Hyderabad food-processing industry validated ROI for upgrading outdated refrigerant-based chillers through an IGA.

India’s Regulatory Framework for Energy Audits

Mandatory Requirements

Under the Energy Conservation Act, 2001, Designated Consumers (DCs) must perform periodic energy audits and appoint certified Energy Managers.

PAT Scheme

The Perform, Achieve, and Trade (PAT) initiative enables industries to trade energy-saving certificates by reducing Specific Energy Consumption.

ISO Standards

ISO 50002 (Energy Audit methodologies) and ISO 50001 (Energy Management Systems) help organizations formalize and institutionalize efficiency improvements.

How Energy Audits Are Conducted: A Structured Workflow

Pre-Audit Preparations

Before conducting the site audit, teams perform a detailed review of available background information, including historical utility bills, equipment inventories, single-line diagrams (SLDs), layout drawings, and past performance data. Trend analysis is carried out to identify anomalies and opportunities for improvement.

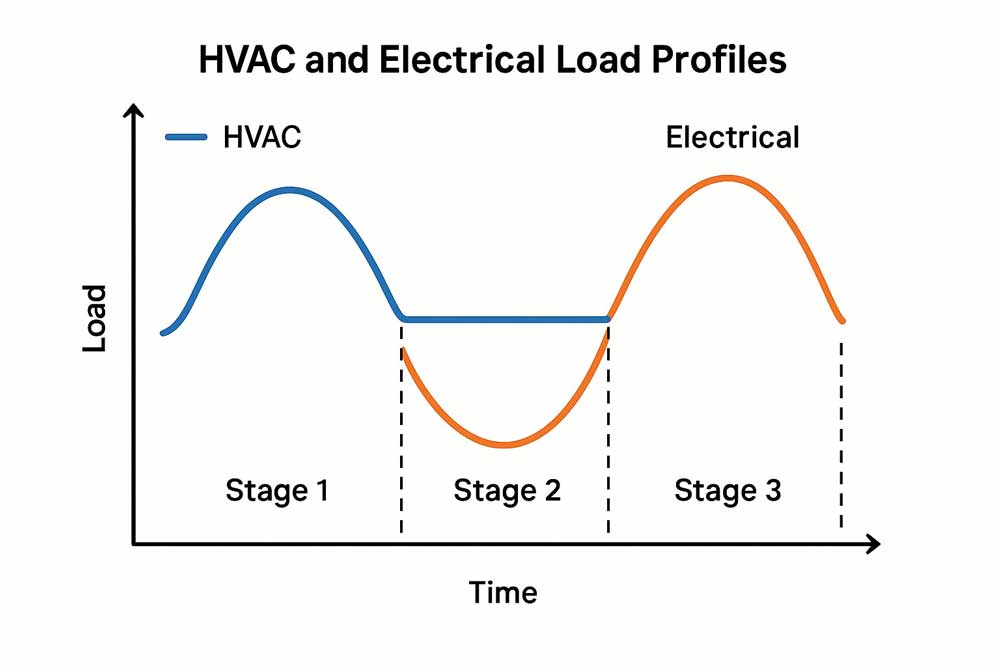

Special attention is given to seasonal load variations. For example, in Chennai IT parks, cooling demand typically peaks between April and June, significantly influencing overall energy consumption patterns.

During the site audit, the following instruments are deployed to measure, verify, and validate system performance:

- Power Quality Analyzer

- Clamp-On Power Hi-Tester

- Thermal Imaging Camera

- Infrared Thermometer

- Temperature Data Logger

- Temperature and Humidity Meter

- Ultrasonic Flow Meter

- Portable Combustion Analyzer

- Portable Dissolved Oxygen Meter

- Lux Meter

- Tachometer

- Anemometer

- Airflow Meter

- Ultrasonic Leak Detector

- Indoor Air Quality (IAQ) Meter

Example: A pharma plant in Baddi used analyzers to identify voltage imbalance causing frequent motor overheating.

Data Analysis and Reporting

Engineers construct an energy balance, benchmark performance, and propose clear Energy Conservation Measures (ECMs).

If the utility bill shows 1000 units consumed but equipment accounts for only 800 units, the remaining 200 units reflect hidden losses.

Frequent Audit Findings and Their Solutions

Electrical Systems

Low power factor leads to penalties. A Kolkata packaging plant eliminated penalties by installing APFC panels.

Voltage imbalance caused overheating; load redistribution resolved it.

HVAC Inefficiencies

Oversized chillers are common in commercial spaces. A Gurugram office tower saved 18% on cooling by adjusting setpoints from 20°C to 24°C and optimizing chiller sequencing.

Compressed Air Systems

Air leakage is a major energy drain.

A Rajkot machine-tool factory saved INR 9 lakh annually by fixing leaks and lowering pressure by 1 bar.

Lighting Systems

Outdated fluorescent lamps and metal halides consume excess energy. LED retrofits in Mumbai logistics hubs dropped lighting loads by nearly 50 percent.

The Strategic Value: ROI, Resilience, and Sustainability

Energy audits often identify 10 to 30 percent energy savings.

No-Cost Measures: Operational discipline, scheduling improvements

Medium Investment: LEDs, VFDs, APFC panels

High Investment: Chiller upgrades, boiler replacements, solar PV integration

Internal Rate of Return (IRR) for energy projects often exceeds 20 to 50 percent. Additionally, audits support ESG disclosures, CSR programs, and compliance audits by providing hard data on Scope 1 and Scope 2 carbon reductions.

Turning Recommendations into Actual Savings

Prioritization Framework

Category A: Immediate fixes (safety and no-cost actions)

Category B: Short-term ROI tasks

Category C: Capital projects requiring budgeting

Monitoring and Verification (M&V)

Sub-metering, EMS dashboards, and periodic reviews ensure that implemented measures deliver sustained benefits and prevent performance drift.

Why Experienced Auditors Matter: Wire Consultancy’s Strength

Energy auditing demands technical depth, cross-functional engineering expertise, and high-accuracy instrumentation. Wire Consultancy brings substantial advantages:

Certified BEE Energy Auditors and Managers

Advanced tools for electrical, thermal, and mechanical diagnostics

Sector-specific experience across chemicals, logistics, food processing, commercial real estate, and retail networks

Action-oriented reporting with vendor-neutral guidance

End-to-end support from diagnostics to implementation and ROI verification

This positioning enables Wire Consultancy to transform energy audits from mere technical assessments into profit-enhancing strategies.

Frequently Asked Questions

What techniques are used during a detailed audit?

Instrument-based measurements, thermal scans, flow assessments, and load monitoring, combined with analytical modelling.

How often should audits be conducted?

Every 2–3 years for most facilities; immediately after expansions, unexpected bill spikes, or major operational changes.

What is the typical ROI?

Low-cost improvements recover cost in months; medium and high-capex projects deliver high IRR and long-term savings.

What does an audit checklist include?

Electrical distribution, motors, HVAC, lighting, compressed air, boilers, steam systems, building envelope, and utility metering.

How do energy audits support sustainability goals?

They quantify carbon reductions, support ESG reporting, and provide data for certifications like SBTi, LEED, GRIHA, and IGBC.

Energy audits have become a strategic necessity for industrial, commercial, and retail operations in India. They provide a data-driven pathway to reduce operating costs, prevent equipment failures, and meet compliance and sustainability goals. When backed by certified expertise, strong diagnostics, and structured implementation, energy audits deliver measurable financial impact and long-term operational resilience.

With industry-aligned methodologies and in-depth experience, Wire Consultancy enables organizations to translate audit insights into performance gains, ensuring that efficiency becomes a continuous and value-generating process.