In high risk environments like manufacturing plants, chemical industries, and large commercial complexes, fire safety is not just a regulatory checkbox—it is a critical operational parameter.

What is a Fire Safety Audit?

A Fire Safety Audit is a systematic, forensic evaluation of an industrial or commercial facility’s fire defense system. Unlike a daily safety round where a supervisor might check if an exit sign is lit, an audit is a deep-dive verification against statutory requirements like the National Building Code (NBC), The Factories Act, and international standards like NFPA.

It answers the critical question: Does our factory’s infrastructure match the specific hazards of our production process?

Fire Risk Assessment (FRA) vs. Fire Safety Audit

In an industrial context, these two terms are often confused but serve distinct phases in the safety lifecycle.

1. Fire Risk Assessment (FRA)

This is the Planning & Identification Phase.

- The Focus: Identifying specific industrial hazards.

- Example: A textile mill identifies cotton dust as a high-risk fuel source.

- Example: A chemical plant identifies static electricity as a potential ignition source near solvent tanks.

- The Output: A qualitative report recommending controls (e.g., “Install anti-static flooring”).

This is the Verification & Compliance Phase.

- The Focus: Testing the controls.

- Example: Verification that the anti-static flooring was actually installed and is being maintained.

- Example: Testing if the cotton dust extraction system is actually functioning to keep dust levels below the explosive limit.

- The Output: A quantitative score and a list of Non-Conformities (NCs).

How to Conduct a Fire Safety Audit in a Factory?

Industrial audits require a rigorous, multi-stage methodology.

- Phase 1: Document Review (The Paper Trail)

- Reviewing “As-Built” drawings to ensure new machinery hasn’t blocked old fire exits.

- Checking files of Annual Maintenance Contracts (AMC) for hydrant pumps and sprinkler systems.

- Verifying “Hot Work Permit” logs for welding and cutting operations.

- Phase 3: Employee Competency Check

- Asking a machine operator: “How do you activate the manual call point?”

- Asking the security team: “Show me how to start the diesel fire pump manually.”

- Phase 4: Gap Analysis & Reporting

- Listing NCs (Non-Conformities) prioritized by risk (e.g., “High Risk: Blocked hydrant access in Zone B”).

The 4 Pillar Audit Framework for Industries

To ensure total compliance, industrial audits evaluate four pillars:

- Prevention: Controlling the hazard source.

- Industrial Context: Proper grounding (earthing) of solvent tanks to prevent static sparks.

- Protection: The hardware readiness.

- Industrial Context: Automatic deluge systems for cooling LPG storage tanks during a fire.

- Management: The systems and culture.

- Industrial Context: Is the “Permit to Work” system actually followed, or just signed blindly?

- Response: The emergency handling.

- Industrial Context: Can the Emergency Response Team (ERT) don breathing apparatus (BA sets) correctly?

The 7 Layers of Industrial Fire Safety

In a factory, relying on just one layer is dangerous. A “Defense in Depth” strategy is required.

- Prevention: Intrinsic safety (e.g., using explosion-proof motors in paint shops).

- Detection: High-sensitivity systems (e.g., VESDA systems in server rooms or Flame Detectors in oil yards).

- Alarm/Notification: Intrinsically safe hooters that won’t spark an explosion in hazardous zones.

- Suppression: Specialized systems (e.g., Foam flooding for oil fires, Gas suppression for electrical panels).

- Compartmentation: Fire curtains or shutters on conveyor belts to stop fire moving between sections.

- Evacuation: Clearly marked aisles on the factory floor, separate from forklift lanes.

- Structural Integrity: Steel columns coated with intumescent paint to prevent collapse during high heat.

The 5 Rules & The Golden Rule for Workers

5 Rules for Factory Floor Safety

- Keep Aisles Clear: Pallets and raw materials must never block the yellow walkways.

- Respect the Red Zone: The area around a fire hydrant or extinguisher must remain empty at all times.

- Report “Near Misses”: If a machine sparks, report it. Next time it might catch fire.

- Know Your Chemical: Know which extinguisher to use. Using water on a chemical fire can cause an explosion.

- Permit First: Never start welding or grinding without a signed Hot Work Permit.

The Golden Rule of Fire Safety

“Life Safety over Asset Protection.”

In an industrial setting, operators often try to save the machine or the batch. The rule is clear: If the fire cannot be fought with one portable extinguisher, hit the Emergency Stop and evacuate.

Technical Deep Dive: Equipment & Ratings

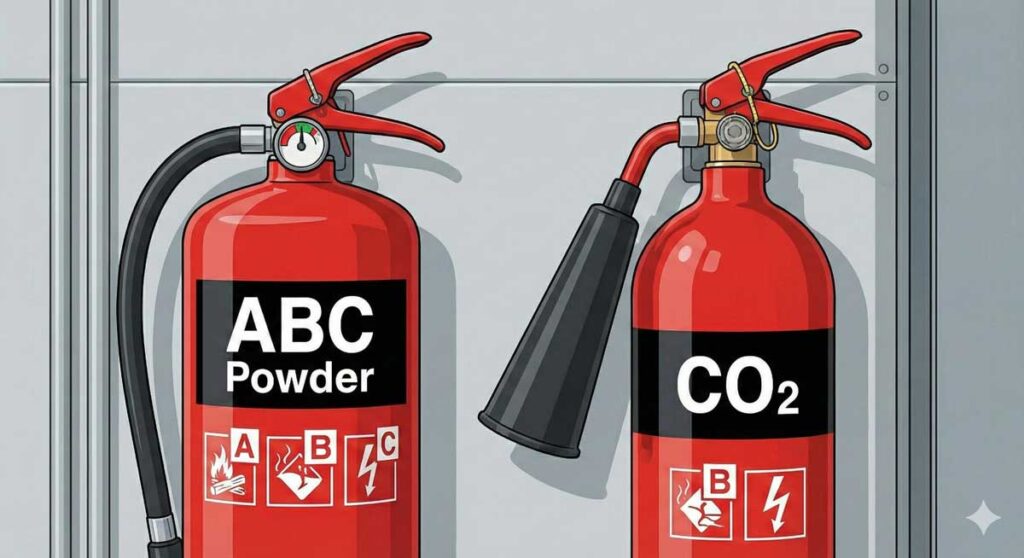

ABC vs. BC Types: Choosing the Right Extinguisher

In a factory, using the wrong extinguisher can be fatal.

- BC Type (CO2 / Dry Powder):

- Best for: Electrical Panels, Transformer Rooms, Solvent Stores.

- Why: It fights Class B (Liquids) and Class C (Electrical) fires effectively.

- ABC Type (Monoammonium Phosphate):

- Best for: Warehouses, Packaging Areas, Admin Blocks.

- Why: It handles Class A (Cardboard/Wood) fires which are common in packaging, as well as general fires.

- Warning: Never use ABC powder on sensitive electronics (like PLC panels) as the residue creates a crust that ruins the circuit. Use CO2 (BC) instead.

FD30 vs. FD30S: The Door Specification

In commercial buildings and factories, fire doors act as critical barriers.

- FD30: A door tested to hold back fire for 30 minutes.

- FD30S: A door tested for 30 minutes PLUS fitted with a Smoke Seal.

- Industrial Application: An FD30 door might be used for a mechanical riser. However, for a door leading from a factory floor to an office corridor, an FD30S is mandatory. It prevents toxic industrial smoke from entering the office escape route.

The 30/30/30 Rule in Construction

For industrial warehousing, this rule often acts as a benchmark for separation walls:

- 30 Minutes Stability: The wall won’t collapse.

- 30 Minutes Integrity: Flames won’t pass through cracks.

- 30 Minutes Insulation: The heat won’t transfer to the other side (preventing ignition of goods stored against the other side of the wall).

The “Take 5” Checklist for Maintenance Teams

Before any maintenance task (like changing a motor or fixing wiring), workers use this micro-tool:

- Stop: Pause and think.

- Look: Is there oil on the floor? Is the area ventilated?

- Assess: Could a spark here cause a fire?

- Manage: Cover the oil, bring a fire watcher.

- Safely Proceed: Begin the work.

How Wire Consultancy Secures Industrial Clients

Managing fire safety in complex environments like refineries, textile mills, or high-rise commercial hubs requires more than a checklist. Wire Consultancy serves as your technical partner in industrial safety engineering.

We support factories and commercial entities by:

- Conducting “Root-Cause” Audits: We don’t just report that a pump failed; we analyze why (e.g., lack of weekly testing or voltage fluctuation).

- Hazardous Area Classification: We help you define your “Zones” (Zone 0, 1, 2) to ensure you are using the correct explosion-proof equipment.

- Load-Specific Risk Assessments: Calculating the specific fire load of your inventory to ensure your sprinkler density is correct.

- Practical ERT Training: Moving beyond classroom theory to conduct real-time evacuation drills and hydrant operation training for your staff.

With Wire Consultancy, you ensure your facility isn’t just compliant with the law, but resilient against the specific risks of your industry.